One of Hottest for Grated Peeled Fresh Ginger - Frozen garlic clove – Nongchuanggang

One of Hottest for Grated Peeled Fresh Ginger - Frozen garlic clove – Nongchuanggang Detail:

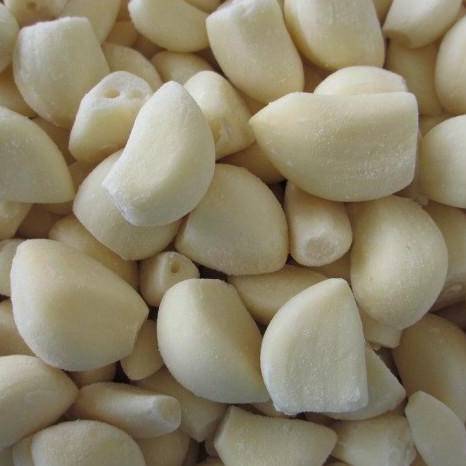

The quick-frozen preserved garlic clove is one of the deep processing products of garlic. With garlic as the main raw material, it has been widely used by the international community. Under normal circumstances, the production of this kind of garlic clove needs raw material inspection, soaking, peeling and other more than 10 steps and processes.

Raw material inspection: raw material are required firstly with a complete shape, no rotten, no damaged, no diseases or insect pests, no sugar garlic cloves and other defective products or impurities.

Soaking: Soak the whole garlic in clean water for about 15~30 minutes to facilitate peeling. Peeling: Peel the soaked garlic with a garlic peeler once. Second peeling: for those not peeled garlic cloves from the machine peeling processing, cloves need to be manually peeled to ensure that the garlic skin to clean.

Grading: Garlic cloves sizes are checked out and graded according to customer’s requirements. Inspections: workshop staff inspection, eliminate diseases and insect pests, bad color, damage, dry scar, rotton spots, and other defective products and impurities.

Disinfection: acceptance of qualified garlic rice in 100 mg/liter of sodium hypochlorite solution immersion 15 minutes, achieve the surface pathogenic bacteria to kill the purpose. Cleaning: Rinse with running water to remove sodium hypochlorite residue solution. Dehydration: remove the moisture on the surface of the garlic rice by air drying machine.

Quick freezing: put the qualified garlic rice after the above series of treatment into the net belt type freezer. The temperature in the production time is below -25℃, and the temperature in the center of the product is below -18℃ after quick-freezing.

Packing: Packing must be carried out in a special clean and sanitary packing room, and the space temperature is required to be controlled within 0~10℃.

Metal detection: all products must pass the metal detector, workshop dedicated personnel to operate, on duty quality control personnel to carry out sensitivity test every hour.

Refrigeration: the packaged products should be put into storage in time. In order to ensure the quality of products, the storage temperature should be kept at -20±2℃ and the center temperature of finished products below -18℃.

| Style | FROZEN |

| Type | Garlic |

| Processing Type | Peeled |

| Freezing Process | IQF |

| Cultivation Type | COMMON |

| Part | WHOLE |

| Shape | Special Shape |

| Packaging | Bulk |

| Grade | A |

| Weight (kg) | 10 |

| Place of Origin | Shandong, China |

| Product name | New season frozen garlic cloves |

| Color | White |

| Material | 100% Fresh Garlic |

| Taste | Typical Taste |

| Size | 150-200/200-280/280-380pcs/kg |

| SHELF LIFE | 24 Months Under -18 Degree |

| Packing | 10 Kg/CTN |

| MOQ | 12 Tons |

| Price Terms | FOB CIF CFR |

| Shipment | Prompt |

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for One of Hottest for Grated Peeled Fresh Ginger - Frozen garlic clove – Nongchuanggang , The product will supply to all over the world, such as: Latvia , Mauritania , Germany , Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.